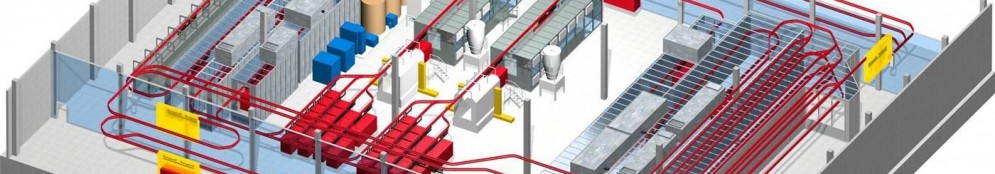

Optimising existing coating processes and finishing plants

Plants and coating equipment have often a technical lifespan of more than 20 years. The economical life however is limited to 8-10 years max.

This means that an installation made 10 years ago, but is still in good technical condition, may no longer meet your company's current needs. Items that possibly would need a closer look in order to (re-)optimise the situation are:

Outdated technology

- Higher energy consumption than necessary,

-

Inefficient processing of raw materials

-

The quality of the coating meets no longer current requirements

Staff problems

-

Inadequate training

-

Change of staff over the years

-

Use of temporary workers

-

Reorganizations,

-

Corporate blindness ("we worked like this during the last 15 years, why change it now?")

Outdated process and plants

-

Coating which no longer meets competitive needs (wet paint instead of powder coating)

-

Pre-treatment, which is no longer allowed (for instance due to environmental requirements, Cr6+)

-

Logistically outdated

-

Higher energy consumption than necessary

-

Inefficient usage of raw materials

-

Substandard coating quality.

Since we want to help you to achieve maximum results at a minimum cost, and because we have no interest in selling you an installation (or part of it), these are the projects where our expertise will be of excellent assistance to you.