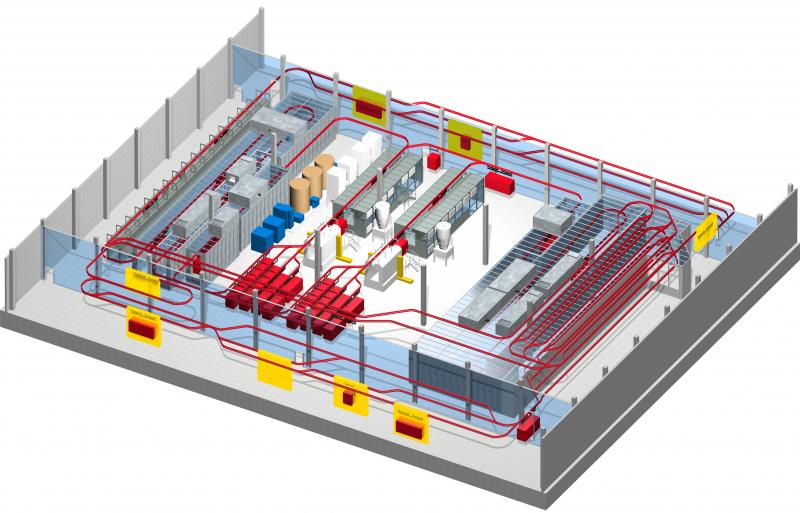

Jungheinrch Landsberg AG, Landsberg

Jungheinrch Landsberg AG, Landsberg

Engineering, construction and projectmanagement at implantion of completely new highly automated powdercoatingplant for internal transport material (forklifts etc.)

-

6-Zone pretreatment

-

2 off automatic powderbooths incl. 3-D system for scanning the parts to be coated

-

IR-gel-oven prior to curing oven

-

Complete ventilation-system of the total workshop, incl. re-use of energy coming out of cooling-zones and ovens

-

Extensive and complex power-and-free conveyorsystem incl. dropsections, buffers, etc. All situated on two floorlevels. Use of two different lenghts of loadbeams in order get maximum flexibility and efficiency